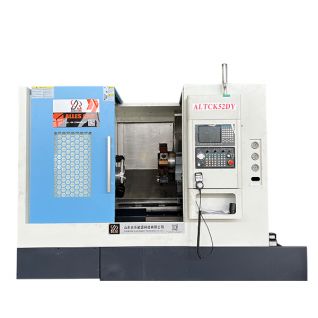

PRODUCT

TCK52D CNC Lathe-Precision, Power, and Productivity Combined

The TCK52D CNC lathe represents a new generation of high-efficiency precision turning machines developed by ALLES CNC. Designed with advanced structural rigidity, stable performance, and intelligent control, it provides users with an ideal solution for precision metal cutting in a wide range of industries such as machinery manufacturing, automotive parts, mold making, and energy equipment.

The TCK52D CNC lathe represents a new generation of high-efficiency precision turning machines developed by ALLES CNC. Designed with advanced structural rigidity, stable performance, and intelligent control, it provides users with an ideal solution for precision metal cutting in a wide range of industries such as machinery manufacturing, automotive parts, mold making, and energy equipment.

1. High Rigidity and Stable Structure

The TCK52D adopts a flat-bed design with a high-strength cast iron base that has been tempered and stress-relieved to ensure long-term stability. The machine structure has undergone finite element analysis (FEA) to guarantee excellent rigidity, vibration resistance, and machining accuracy. Its robust body enables it to handle heavy-duty cutting while maintaining precision in continuous production.

The wide guideways and optimized chip removal design ensure durability and smooth operation. Combined with precision ball screws and linear motion systems, the lathe minimizes backlash and delivers smooth axis movement, ensuring accurate and consistent results even during high-speed cutting.

2. Powerful Spindle and Efficient Transmission

The TCK52D CNC lathe is equipped with a high-torque main spindle, which provides powerful cutting capability for both steel and non-ferrous materials. The spindle system uses high-precision bearings to achieve excellent rotational accuracy and low noise during operation.

The spindle bore diameter allows the machining of medium-sized shafts and pipe-type workpieces, making it a versatile choice for various applications. The variable speed drive and programmable control ensure precise control over spindle speed and cutting feed, enhancing flexibility for both rough and finish machining.

3. Advanced CNC Control System

The machine can be configured with popular control systems such as GSK, Fanuc, or Siemens, depending on customer requirements. The CNC controller offers intuitive operation, high processing speed, and stable performance. With multi-language interfaces and user-friendly programming, it reduces setup time and improves operator efficiency.

The TCK52D supports manual, semi-automatic, and full CNC operation, providing flexibility for various production needs. It also supports G-code and conversational programming, allowing operators to quickly adapt and optimize machining parameters.

4. High Efficiency and Wide Application

Thanks to its rigid structure and intelligent control, the TCK52D achieves excellent cutting precision and repeatability. It is capable of performing complex turning operations such as external and internal turning, facing, tapering, threading, and grooving.

This CNC lathe is widely used in manufacturing automotive parts, hydraulic components, shafts, valves, and flanges. Its excellent stability under long working hours makes it suitable for batch production as well as small-lot precision machining.

5. Safety, Maintenance, and Humanized Design

Operator safety and convenience have been carefully considered in the TCK52D’s design. The full-enclosure protection system prevents chips and coolant from escaping, ensuring a clean and safe working environment. The control panel layout is ergonomic, allowing easy operation and quick parameter adjustment.

Maintenance is simple and convenient. The automatic lubrication system ensures continuous oil supply to key components such as guideways and screws, extending machine life and maintaining precision.

In addition, the electrical cabinet features heat dissipation and dust-proof design, improving long-term reliability.

6. Customization and After-Sales Support

ALLES CNC provides multiple customization options for the TCK52D, including optional hydraulic chuck, tailstock, tool post type (4-station or 6-station), and automatic chip conveyor. Customers can choose spindle speed range, control system, and automation level based on their specific production needs.

The company offers comprehensive after-sales support, including online technical assistance, spare parts supply, and remote diagnostics. This ensures customers can maintain stable production and minimize downtime.

7.Specification:

| Item | Specification (TCK52D) |

|---|---|

| Maximum Swing over Bed | Φ520 mm |

| Maximum Machining Diameter on Tool Post | Φ280 mm |

| Maximum Machining Length | 520 / 750 mm |

| Distance Between Centers | 600 / 830 mm |

| Spindle Maximum Speed | 4200 rpm |

| Spindle Bore Diameter | Φ66 mm |

| Bar Capacity | Φ52 mm |

| X/Z Axis Screw Specification | 3210 / 4010 |

| X Axis Travel | 270 mm |

| X/Z Axis Linear Guideway | 45 / 45 mm |

| Z Axis Travel | 550 / 750 mm |

| C Axis | 360° |

| Turret | 12-station driven turret |

| Tool Size | 25 × 25 / 32 mm |

| Powered Tool Model | BMT55 ER32 |

| Machine Dimensions (L × W × H) | 3000 × 1850 × 1710 mm |

| Approx. Weight | 3800 / 4100 kg |