PRODUCT

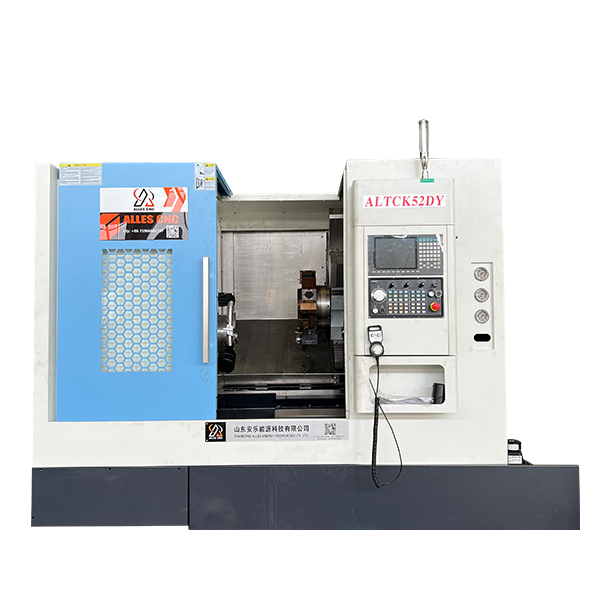

TCK52DY CNC Lathe — High Precision, High Efficiency Turning Solution

The TCK52DY CNC lathe is a state-of-the-art turning machine engineered for precision, reliability, and productivity. Designed by ALLES CNC, this advanced machine combines high rigidity, robust construction, and intelligent CNC control to meet the growing demands of modern metalworking industries. It is suitable for a wide range of applications including automotive components, mold making, machinery parts, and industrial metal processing.

The TCK52DY CNC lathe is a state-of-the-art turning machine engineered for precision, reliability, and productivity. Designed by ALLES CNC, this advanced machine combines high rigidity, robust construction, and intelligent CNC control to meet the growing demands of modern metalworking industries. It is suitable for a wide range of applications including automotive components, mold making, machinery parts, and industrial metal processing.

1. Robust Design and Superior Rigidity

The TCK52DY adopts a heavy-duty flat-bed design made of high-quality cast iron that has been stress-relieved and tempered to reduce deformation over time. Its optimized structural design ensures excellent rigidity, which minimizes vibration and maintains machining accuracy during high-speed or heavy-duty operations.

The lathe's wide guideways, precise ball screws, and linear motion systems reduce backlash and ensure smooth and accurate axis movement. This structural stability allows the TCK52DY to handle large and heavy workpieces without compromising on precision.

2. Powerful Spindle and Versatile Machining Capacity

Equipped with a high-torque spindle, the TCK52DY can efficiently machine a wide range of metals including steel, aluminum, and alloys. The spindle system is supported by high-precision bearings, ensuring rotational accuracy, low noise, and minimal vibration.

The machine features a generous spindle bore diameter and supports bar capacity suitable for medium to large workpieces, making it highly versatile for different industrial applications. With a maximum spindle speed of up to 4200 rpm, operators can perform both roughing and finishing operations efficiently.

3. Advanced CNC Control System

The TCK52DY can be equipped with popular CNC controllers such as Fanuc, Siemens, or GSK, offering high-speed processing, intuitive operation, and reliable performance. The control system supports G-code programming, conversational programming, and multi-language interface, making it accessible to operators with varying levels of experience.

The lathe supports manual, semi-automatic, and fully automatic operations, enabling flexible production for small batches, mass production, and prototype work.

4. High-Precision Multi-Axis Operation

With X and Z axis control, and a C-axis capable of 360° rotation, the TCK52DY can perform complex turning operations such as facing, tapering, threading, grooving, and contouring. Its 12-station driven turret allows for multiple tool operations without frequent tool changes, increasing machining efficiency.

The machine also supports driven tools (BMT55 ER32), enabling milling, drilling, and tapping operations on the lathe, which reduces the need for secondary processes and saves production time.

5. Optimized Productivity and Workpiece Handling

The TCK52DY is designed to accommodate workpieces up to 520–750 mm in length and a maximum weight of 3800–4100 kg, providing flexibility for various industrial components. Its flat-bed design and rigid structure ensure that even long or heavy parts remain stable during machining.

The lathe’s ergonomic layout, intuitive control panel, and smooth axis travel improve operator efficiency, allowing for long working hours without fatigue. In addition, automated lubrication and cooling systems maintain tool and machine longevity.

6. Safety, Maintenance, and Human-Centered Design

Operator safety is a priority in the TCK52DY. Fully enclosed guards prevent chips and coolant from escaping, maintaining a clean and safe workspace. Emergency stop buttons and safety interlocks ensure operational security.

Maintenance is simplified with automatic lubrication systems for the guideways, screws, and turret, as well as easily accessible electrical cabinets with dust-proof and heat-dissipation design. This ensures long-term reliability and minimal downtime.

7. Applications Across Industries

The TCK52DY is widely used in automotive, machinery, mold, and energy industries. It excels in producing precision shafts, flanges, hydraulic components, valves, and various custom mechanical parts. Its flexibility allows manufacturers to handle both small-batch and high-volume production efficiently.

With the capability to handle complex geometries and tight tolerances, it is particularly well-suited for companies that require high-precision, high-repeatability machining without compromising efficiency.

8. Customization and After-Sales Support

ALLES CNC offers a range of customization options for the TCK52DY, including optional hydraulic chucks, tailstocks, tool turret configurations, and chip conveyors. Customers can choose spindle speed, control system, and automation level according to their production requirements.

| Item | Specification (TCK52DY) |

|---|---|

| Maximum Swing over Bed | Φ650 mm |

| Maximum Machining Diameter on Tool Post | Φ400 mm |

| Maximum Machining Length | 450 / 680 mm |

| Distance Between Centers | 600 / 830 mm |

| Spindle Motor Power | 11–15 kW |

| Spindle Maximum Speed | 4200 rpm |

| Spindle Bore Diameter | Φ66 mm |

| Bar Capacity | Φ52 mm |

| X/Z Axis Screw Specification | 3210 / 4010 |

| X Axis Travel | 270 mm |

| X/Z Axis Linear Guideway | 45 / 45 mm |

| Z Axis Travel | 550 / 750 mm |

| Y Axis Travel | ±45 mm (Linear Guide Type) |

| C Axis | 360° |

| Turret | 12-station driven turret with Y axis |

| Sleeve Diameter | 80 mm |

| Sleeve Travel | 100 mm |

| Tailstock Maximum Travel | 480 mm |

| Tailstock Quill Taper | MT5 |

| Machine Dimensions (L × W × H) | 3000 × 1850 × 1710 mm |

| Approx. Weight | 4000 / 4300 kg |