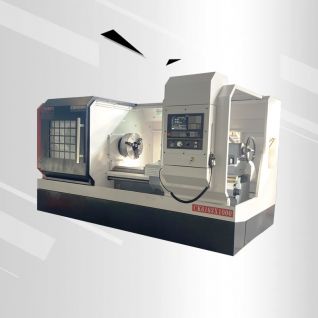

PRODUCT

Metal CNC lathe AKCJ6163X1000

ALCK6163X1000 CNC Lathe is a high-performance machining center designed for medium-to-large workpieces, combining high precision, rigidity, and efficiency. It meets the demanding requirements of modern manufacturing for complex part processing. This machine is widely applicable in automotive, aerospace, energy equipment, heavy machinery, and general mechanical manufacturing industries. It not only enhances production efficiency but also ensures consistent machining quality, making it an essential tool for optimizing production processes and improving enterprise competitiveness. With its outstanding machining capabilities, intelligent control system, and robust structural design, the ALCK6163X1000 performs exceptionally in medium-to-large part machining, becoming a reliable partner for manufacturers.

ALCK6163X1000 CNC Lathe is a high-performance machining center designed for medium-to-large workpieces, combining high precision, rigidity, and efficiency. It meets the demanding requirements of modern manufacturing for complex part processing. This machine is widely applicable in automotive, aerospace, energy equipment, heavy machinery, and general mechanical manufacturing industries. It not only enhances production efficiency but also ensures consistent machining quality, making it an essential tool for optimizing production processes and improving enterprise competitiveness. With its outstanding machining capabilities, intelligent control system, and robust structural design, the ALCK6163X1000 performs exceptionally in medium-to-large part machining, becoming a reliable partner for manufacturers.

1. Advantages

The ALCK6163X1000 demonstrates significant advantages in precision, efficiency, and reliability. Its high-precision spindle and advanced servo system enable micron-level machining accuracy, while the optimized bed structure and wide guideways minimize cutting vibrations, ensuring superior surface finish and dimensional consistency. The machine delivers ample power with a high-torque spindle and high-power motor, maintaining stable cutting even when machining large-diameter or high-hardness materials. It performs reliably over long continuous operations, significantly enhancing production efficiency. The integral cast bed is annealed and precision-processed, providing high rigidity and vibration resistance, which ensures stable operation under heavy cutting conditions while minimizing part deformation and dimensional errors. Additionally, the machine is equipped with comprehensive protective systems, automatic lubrication, and cooling management, guaranteeing long-term reliability and reducing maintenance costs, offering a solid foundation for production operations.

2. Features

The ALCK6163X1000 is equipped with multiple features that enhance machining efficiency and operational convenience. It features a high-precision spindle and multi-station tool turret, supporting compound machining to reduce tool change times and improve production efficiency. The wide guideways and robust bed ensure high precision and excellent surface finish under heavy cutting conditions. The CNC system supports multi-axis simultaneous machining, allowing complex parts to be completed in a single setup, significantly shortening production cycles. Automatic lubrication and cooling systems maintain long-term stable operation, while multiple stored programs and quick-recall functions facilitate repeat production. The user-friendly interface is intuitive and easy to operate, and key components are arranged for convenient daily maintenance and servicing. These features not only enhance machining capabilities but also improve operational experience, making the production process more efficient and intelligent.

3. Application Industries

The ALCK6163X1000 is widely applied across various industries. In automotive manufacturing, it efficiently machines engine components, transmission systems, and chassis parts, ensuring dimensional accuracy and surface quality for large-diameter shafts and complex structures, meeting stringent automotive production requirements. In aerospace, it is suitable for machining high-precision parts such as aircraft engine components and airframe structures. Its high rigidity and precision ensure stable and reliable processing of complex parts, meeting the high standards of the aerospace industry. In energy equipment manufacturing, it can machine components for wind turbines, nuclear power, and petroleum machinery, including large-diameter shafts and high-hardness materials, ensuring equipment reliability and durability. In heavy machinery and engineering equipment, it can process large hydraulic assemblies, construction machinery parts, and mining equipment components. With its rigid bed, powerful spindle, and intelligent CNC system, it delivers high-efficiency, high-precision machining to meet the demands of heavy-duty operations. Furthermore, it is suitable for medium-to-large part machining, mold processing, and complex part production, balancing precision and productivity to meet diverse manufacturing needs.

4. Coclusion

In summary, the ALCK6163X1000 CNC Lathe combines high precision, rigidity, efficiency, and intelligent operation, making it a top choice for medium-to-large part machining. Its high-performance spindle system, advanced CNC capabilities, and well-designed operation and maintenance features not only significantly improve production efficiency but also ensure consistent part quality. Whether in automotive, aerospace, energy equipment, heavy machinery, or general mechanical manufacturing, the ALCK6163X1000 provides stable and reliable machining solutions, offering enterprises a competitive edge and long-term growth potential.

Product Specifications:

| Project | Content | Unit | CK6163*1000 |

| Processing range | Maximum turning diameter of bed | mm | Φ630 |

| Maximum turning diameter on skateboard | mm | Ф400 | |

| Maximum processing length | mm | 1000 | |

| Maximum machining diameter | mm | Φ630 | |

| Travel | X/Z axis maximum travel | mm | 330/1000 |

| X/Z axis minimum displacement unit | mm | 0.001 |