PRODUCT

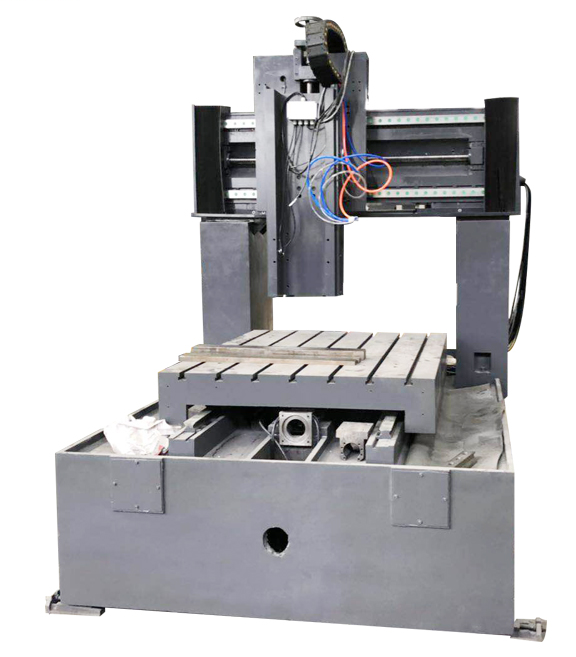

Gantry milling machine ALGMC1417

The ALGMC1417 gantry milling machine is a CNC machine tailored for large, heavy, and high-precision machining tasks. It combines an ultra-large machining envelope, powerful cutting capabilities, and stable accuracy, making it particularly suitable for machining core components in the aerospace, shipbuilding, rail transportation, and energy equipment industries.

The ALGMC1417 gantry milling machine is a CNC machine tailored for large, heavy, and high-precision machining tasks. It combines an ultra-large machining envelope, powerful cutting capabilities, and stable accuracy, making it particularly suitable for machining core components in the aerospace, shipbuilding, rail transportation, and energy equipment industries.

1. Key Advantages

Extremely Large Working Space: Ample X, Y, and Z axis travel accommodates extra-long, wide, and tall workpieces, enabling multi-station machining with a single clamping setup.

Highly Rigid Structural Design: The gantry frame and worktable are constructed of high-strength cast iron/welded components, aged to ensure structural stability and deformation resistance.

High Precision and High Efficiency: Equipped with a high-resolution linear scale, imported roller guides, and precision lead screws, it ensures micron-level machining accuracy.

Versatile Milling Capabilities: Configurable with right-angle milling heads, universal milling heads, and an automatic tool changer (ATC) system, it accommodates complex shapes and multi-angle machining.

Automation and Intelligence: Supports automatic lubrication, chip conveying, and remote monitoring, improving production efficiency and ease of maintenance.

2 Application Industries

Aerospace: Machining of aircraft wing spars, fuselage frames, large structural components, and engine parts.

Shipbuilding: Manufacturing of hull keels, deck beams, and large propeller molds.

Rail Transit: Machining of high-speed rail and subway vehicle underframes, end walls, and key aluminum alloy components.

Energy Equipment: Manufacturing of wind turbine nacelles, large generator bases, and nuclear power plant components.

Mold Manufacturing: Manufacturing of large automotive panel molds, die-casting molds, and engineering machinery molds.

3.Product Specifications:

| Item | Unit | ALGMC1417 |

| Worktable | Worktable load (KG) | 2500 |

| Worktable size (mm) | 1400*1700 | |

| T-slot width | 18mm | |

| Dimensions | L*W*H(m)(About) | 4*2,3*2,6~2,9 |

| X.Y.Z Axis | Travel (mm) | 1400*1700*450 |

| X.Y axis fast moving speed(no load)( mm/min) | 8000-12000 | |

| Z axis fast moving speed(mm/min) | 7000-10000 | |

| Fastest processing speed(mm/min) | 6000 | |

| Positioning accuracy(mm) | 0,02/300 | |

| Re-positioning accuracy(mm) | 0,02 |