PRODUCT

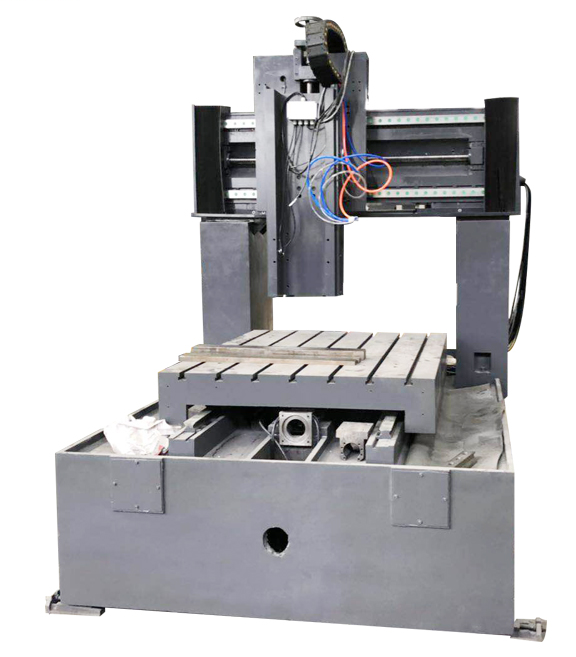

Gantry milling machine ALGMC1311

The ALGMC1311 gantry milling machine is a high-rigidity, high-precision, large-scale machining equipment designed for heavy-duty cutting and complex component processing. It combines stability, efficiency, and adaptability, making it widely applicable in industries requiring the highest precision and processing capabilities, such as aerospace, shipbuilding, and energy equipment.

The ALGMC1311 gantry milling machine is a high-rigidity, high-precision, large-scale machining equipment designed for heavy-duty cutting and complex component processing. It combines stability, efficiency, and adaptability, making it widely applicable in industries requiring the highest precision and processing capabilities, such as aerospace, shipbuilding, and energy equipment.

1. Key Advantages and Features

Strong Structural Stability: The gantry frame is constructed of high-strength cast iron or welded construction, with multiple stress-relief treatments, ensuring stable accuracy over extended operation.

Outstanding Processing Capabilities: The long-stroke design accommodates extra-long, extra-wide, and extra-heavy workpieces, enabling multi-sided machining in a single clamping.

High-Precision Control System: Equipped with an advanced CNC system and high-resolution linear encoder, it achieves micron-level positioning accuracy.

Diverse Tool Configurations: It can accommodate a variety of milling heads (right-angle milling heads, universal milling heads, etc.) to accommodate machining of various angles and curved surfaces.

Automation and Intelligence: Supports automatic tool changing (ATC), automatic lubrication, and condition monitoring, improving processing efficiency and equipment life.

2. Major Application Industries

Aerospace: Processing of large aluminum and titanium alloy structural components, such as aircraft fuselage frames, wing spars, and engine components.

Shipbuilding: Processing of hull frames, large propeller molds, and deck structures.

Energy Equipment: Processing of wind turbine nacelle frames, hydropower unit bases, and nuclear reactor supports.

Rail Transit: Processing of underframes, end walls, and aluminum alloy structural components for high-speed rail and subway vehicles.

Mold Manufacturing: Processing of large automotive panel molds, die-casting molds, and forming molds.

3.Product Specifications:

| Item | Unit | ALGMC1311 |

| Worktable | Worktable load (KG) | 2000 |

| Worktable size (mm) | 1100*1300 | |

| T-slot width | 18mm | |

| Dimensions | L*W*H(m)(About) | 3,7*2,1*2,6~2,9 |

| X.Y.Z Axis | Travel (mm) | 1100*1300*450 |

| X.Y axis fast moving speed(no load)( mm/min) | 8000-12000 | |

| Z axis fast moving speed(mm/min) | 7000-10000 | |

| Fastest processing speed(mm/min) | 6000 | |

| Positioning accuracy(mm) | +-0.01/300 | |

| Re-positioning accuracy(mm) | +-0.01 |