PRODUCT

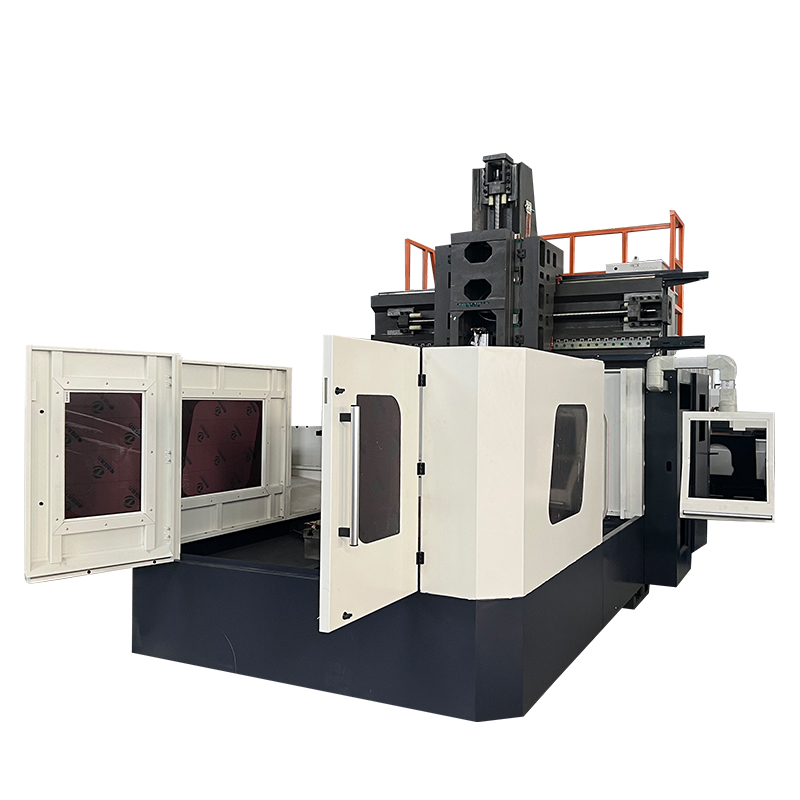

Gantry milling machine ALGMC1090

The ALGMC1090 is a fixed-beam CNC gantry milling machine designed for efficient machining of medium-to-large workpieces. It offers multiple advantages, including stable structure, reliable precision, and a wide range of applications. It is widely used in industries such as mold manufacturing, mechanical parts, automotive, and energy.

The ALGMC1090 is a fixed-beam CNC gantry milling machine designed for efficient machining of medium-to-large workpieces. It offers multiple advantages, including stable structure, reliable precision, and a wide range of applications. It is widely used in industries such as mold manufacturing, mechanical parts, automotive, and energy.

1. Stable Structure, Suitable for Heavy-Load Machining

The fixed-beam gantry structure features a fixed crossbeam and minimal moving parts, ensuring high rigidity and structural stability.

The main casting is made of high-strength cast iron with resin-bonded sand, providing excellent overall vibration resistance and resisting deformation during long-term operation.

2. Large Travel and Load Capacity, Meeting Various Machining Requirements

The three-axis travel is 900mm (X) × 1000mm (Y) × 450mm (Z), accommodating parts of various sizes.

The worktable measures 900×1000mm and has a maximum load capacity of 2000kg, supporting heavy-duty machining.

3. Precise and Reliable Drive System

All three axes utilize a combination of ball screws and linear guides, ensuring smooth transmission and responsiveness.

Precision machining and high-speed operation are combined to effectively improve efficiency and accuracy.

4. Flexible and Compatible Control System

Supports CNC systems from multiple brands, including FANUC, Siemens, and Guangshu, meeting diverse customer needs.

Optional Automatic Tool Changer (ATC) enhances machining automation.

5. Widely Applicable to Multiple Industries

Suitable for molds, automotive parts, hardware components, construction machinery, and energy applications.

Enables integrated processing of complex processes such as milling, drilling, and tapping.

6.Product Specifications:

| Item | Unit | ALGMC1012 |

| Worktable | Worktable load (KG) | 2000 |

| Worktable size (mm) | 900*1000 | |

| T-slot width | 18mm | |

| Dimensions | L*W*H(m)(About) | 3.4*2.3*2.6~2.9(Highest) |

| X.Y.Z Axis | Travel (mm) | 1000*1200*450 |

| X.Y axis fast moving speed(no load)( mm/min) | 8000-15000 | |

| Z axis fast moving speed(mm/min) | 7000-10000 | |

| Fastest processing speed(mm/min) | 6000 | |

| Positioning accuracy(mm) | +-0.01/300 | |

| Re-positioning accuracy(mm) | +-0.01 |