PRODUCT

The CK6140X750 CNC lathe is a precision machining tool designed for efficient metal turning. With a maximum swing length of 400 mm and a machining length of 750 mm, it is suitable for machining small and medium-sized parts. This model is known for its sturdy structure, stable performance and easy operation, and is widely used in industries such as automobiles, machinery, mold manufacturing and repair workshops. It supports manual and automatic operation to ensure the accuracy and production efficiency of various machining tasks.

The application industries of the CNC lathe CK6140X750:

Automobile manufacturing: used for machining high-precision metal parts such as engine parts, transmission shafts, brake discs, etc.

Mechanical processing industry: widely used in precision turning of various mechanical parts, such as shafts, sleeves, and flanges.

Mold manufacturing industry: suitable for mold accessories and metal parts with complex shapes.

Hardware tool industry: can be used to produce hardware accessories, small tool parts, etc.

Maintenance service industry: used in daily factory maintenance scenarios such as equipment maintenance and part remaking.

Teaching and vocational training: Suitable for CNC teaching and training equipment in technical schools, engineering colleges and other institutions.

Aerospace (supporting small and medium-sized enterprises): Processing structural parts, connectors and other parts with high dimensional accuracy requirements.

Power and energy industry: Used for processing accessories, flanges and fasteners in power equipment.

CK6140X750 has become an ideal choice for small and medium-volume precision processing in many industries with its high cost-effectiveness and flexible processing capabilities.

Product Parameters:

| Model | CK6140x750 | |

| Processing capacity | Maximum turning diameter of bed | 400mm |

| Maximum turning diameter on the tool post | 220mm | |

| Center distance | 750mm | |

| Rail width | 360mm | |

| X stroke | 250mm | |

| Z-stroke | 900mm | |

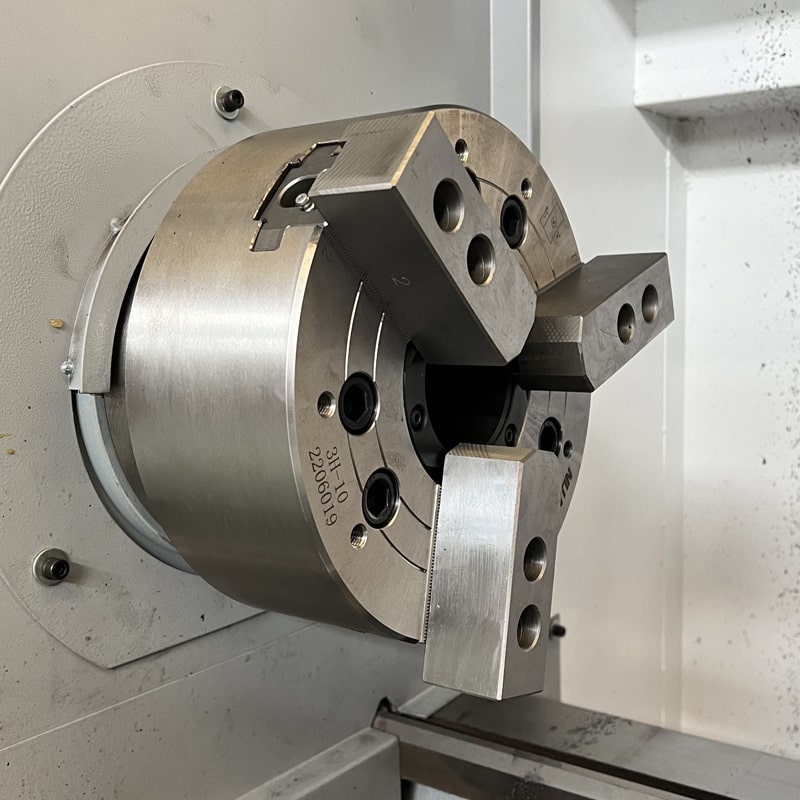

| Headstock | Spindle hole diameter | 52mm |

| Spindle end type | ISO-C6 | |

| Taper of spindle bore | MT6 | |

| Spindle speed range (number of stages) | Gear two-speed 50-1600rpm/single axis 2200rpm (optional) | |

| Skateboard | Fast moving speed of carriage | X/Z:5/8m/min |

| Repeatability | Z:0.013mm X:0.012mm | |

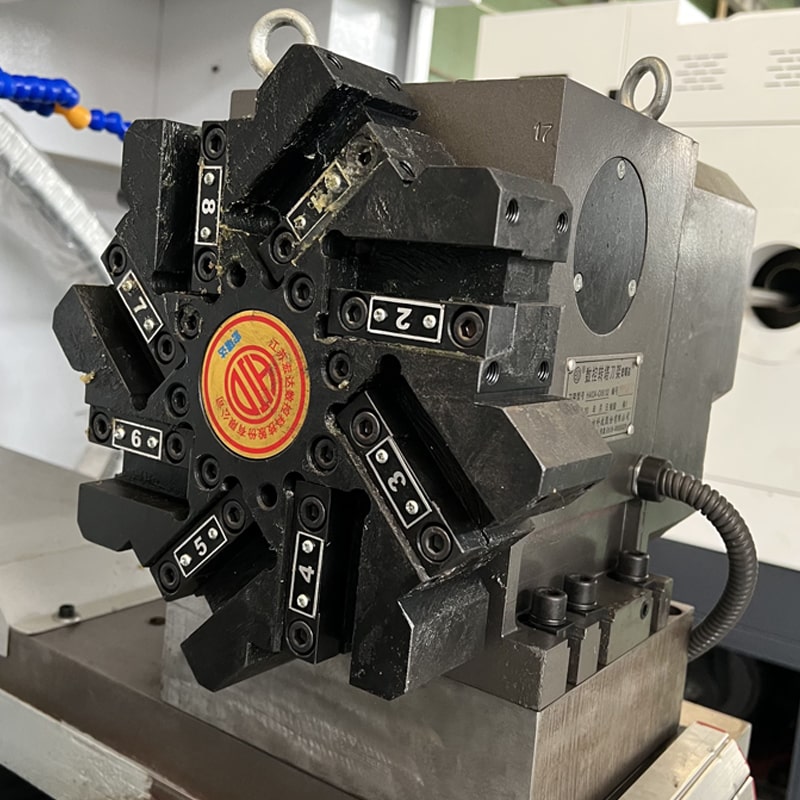

| Number of tools | 4 | |

| Tool change time | 1sec | |

| Tailstock | Diameter of tailstock sleeve | 65mm |

| Taper of tailstock sleeve | MT4 | |

| Maximum stroke of tailstock sleeve | 120mm | |

| Motor | Servo main motor power | 5.5KW |

| Cooling pump | 125W | |

| PACKING(L*W*H) | 2350*1400*1800mm | |

| WEIGHT(N.W/G.W) | 1550/1650kg | |