Company News

ALCK6140X750 three CNC lathes successfully completed equipment inspection

Recently, three ALCK6140X750 CNC lathes meticulously developed and manufactured by ALLES CNC completed a multi-day equipment inspection in the company's workshop. This inspection not only fully demonstrated the machine's advantages in precision, stability, and operational performance, but also provided strong assurance for the upcoming mass production delivery to customers.

Overall, the ALCK6140X750 is a classic general-purpose CNC lathe, characterized by its compact structure, high machining accuracy, and wide applicability. During the inspection process, the three machines underwent comprehensive structural testing, long-term operational testing, accuracy assessment, and trial cutting of customer workpieces. All data met or even exceeded national standards, successfully passing factory inspection.

In terms of mechanical structure, all three ALCK6140X750 machines feature high-strength cast iron bed frames, providing strong overall rigidity and excellent vibration resistance. During the inspection, the machines operated continuously for over 72 hours, with stable spindle rotation and no abnormal noise from the transmission system, demonstrating excellent durability and reliability. All three machines performed reliably in comparative tests involving high-speed and heavy cutting, with effective control of thermal deformation of the machine bed ensuring consistent machining.

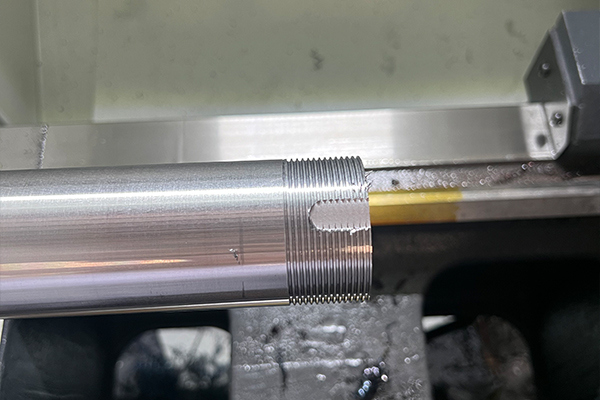

In terms of machining accuracy, all three machines met high-precision standards through testing for roundness, coaxiality, and surface roughness. In particular, in trial cutting of actual customer-provided workpieces, dimensional errors were kept within extremely narrow limits, and surface finish was ideal, fully meeting the quality requirements for mass production. This result not only validates the machine's high-precision machining capabilities but also strengthens customer confidence in ALLES CNC products.

In terms of operation and system performance, the ALCK6140X750 is equipped with a mature and stable CNC system with an intuitive user interface, facilitating programming and debugging. All three machines demonstrated flexible operation and stable electrical performance during machine inspections. Safety protection and user-friendly design also make the machines ideally suited for daily use in customer workshops.

In terms of application, the three ALCK6140X750 machines will be widely used in industries such as automotive parts, machining, instrument manufacturing, and education and training. Whether producing high-precision small parts or medium-volume components, this machine model provides efficient and stable machining solutions. The simultaneous inspection of all three units demonstrates ALLES CNC's strong capabilities in meeting customers' volume purchasing and standardized quality requirements.

In summary, the successful completion of the inspection of the three ALCK6140X750 CNC lathes not only demonstrates ALLES CNC's expertise in CNC machine tool manufacturing but also lays a solid foundation for the customer's continued efficient production. Going forward, ALLES CNC will continue to uphold the principles of quality and customer first, providing more advanced and reliable CNC equipment to global users.